The mDATA® utility program includes the OUTLIER function which removes noise and/or non-normal measurements from the lot history record. This modification is allowed when it is understood that a process is in place to detect and eliminate the tubing that contains the outlier (for example, via manual inspection). Typically an outlier occurs due to a mechanical issue (i.e. the wire line is moved out of the laser micrometer measurement window accidentally) and/or results from an actual defect such as a lump or blister.

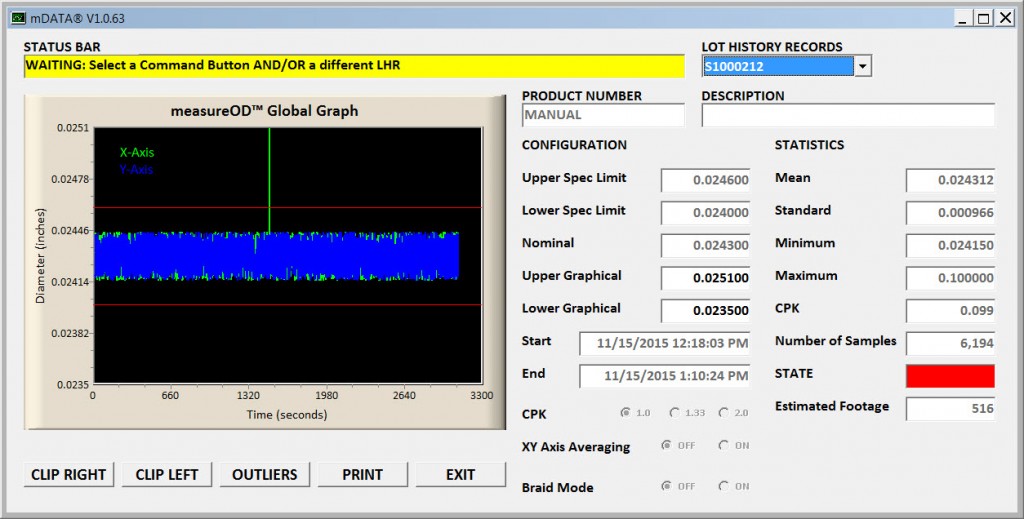

The following example illustrates the use of the OUTLIER function. In the following case, a defect is measured at the 1,500 second mark with an OD measurement of 0.1 inches. The resulting CPK for the lot would ordinarily result in the spool or manufactured lot to be rejected (CPK = 0.099).

In this case, the mDATA® Utility program is utilized to review and modify the lot history data using the OUTLIER function.

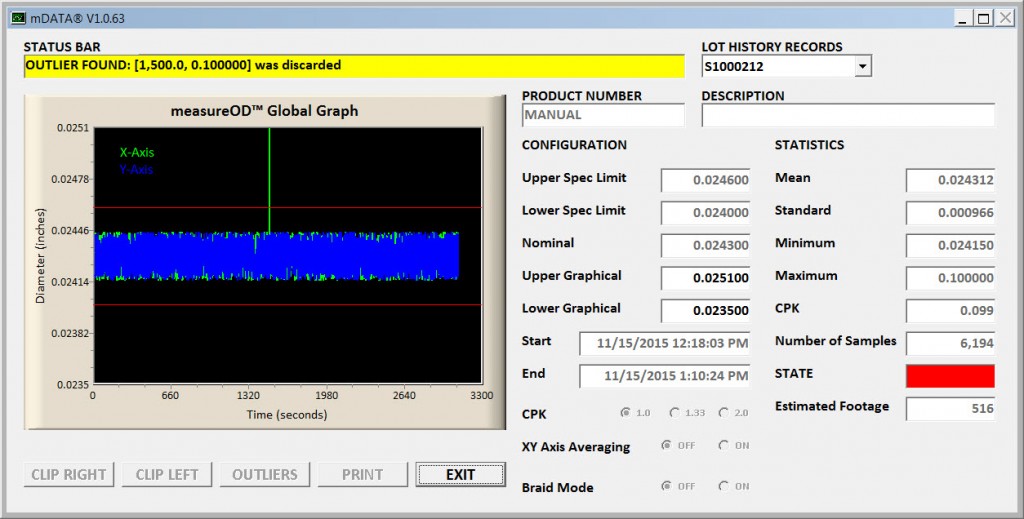

The OUTLIER function is selected and the mDATA® program automatically identifies that the identity of the OUTLIER data point as shown in the STATUS BAR.

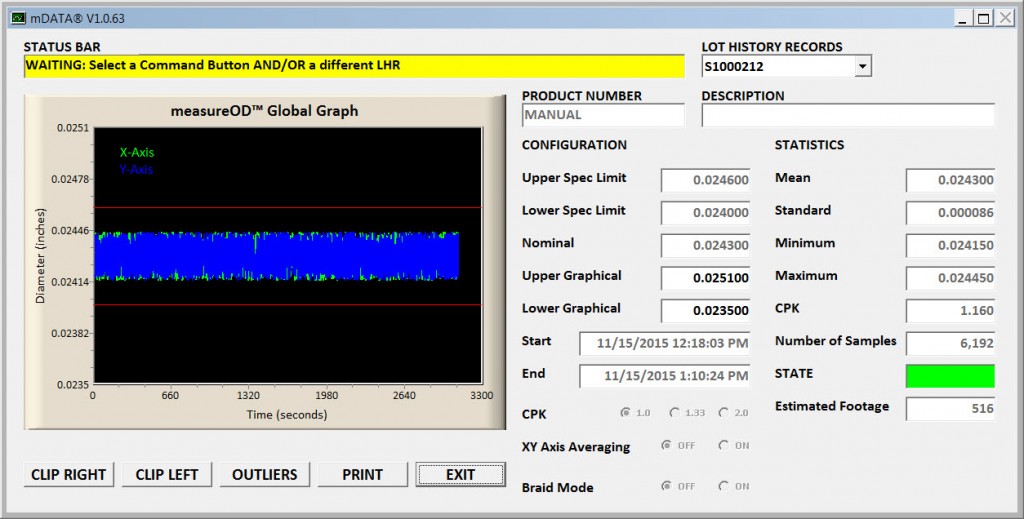

After the data point is removed, the mDATA® utility program automatically recomputes the statistics for the manufactured lot. With the outlier data point removed, the new CPK is computed as 1.160. In this example, this lot is considered GOOD since it meets the statistical requirement of CPK>=1.0.